Category

Reverse Air Baghouse GSM750/800 Woven Fiberglass Filter Bag with PTFE Membrane

Fiberglass bag filter specifications 1.The material of the polyeser filter bag: (1) 100% POLYESTER (2) ANTI-STATIC POLYE

Basic Info.

| Model NO. | 150x80000 |

| Filtration Grade | Medium Filter |

| Filter Bag Sectional Shape | Round Bag |

| Filter Bag Environment | High-Temperature |

| Cartridge Installation | Vertical Lifting |

| Package | Export Standard |

| Transport Package | Carton Box |

| Specification | 160x3000mm |

| Trademark | xiechang |

| Origin | China |

Product Description

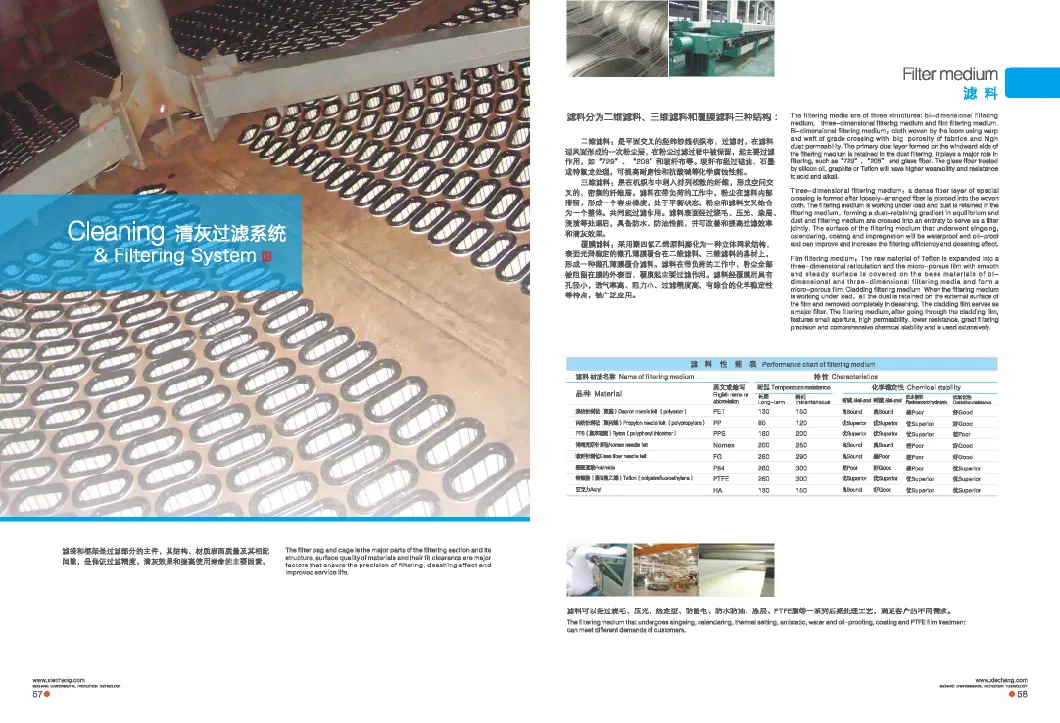

Fiberglass bag filter specificationsFiber Composition | Polyester | Polyester with PTFE membrane | PTFE | FMS | P84 | PPS | Nomex |

| Weight (g/m2) | 500 | 500 | 750-800 | 800 | 500 | 500-550 | 450-600 |

| Thickness (mm) | 1.7-2.0 | 1.7-2.0 | 1.2-1.6 | 1.8-3 | 2.1 | 1.8-2.0 | 1.9-2.4 |

| Running Temperature (°C) | 130 | 130 | 240 | 200 | 180 | 160 | 200 |

| Peak Temperature (°C) | 150 | 150 | 260 | 280 | 260 | 190 | 240 |

| Air Permeability (M3/M2.S. 200Pa) | 8-12 | 8-12 | 5-8 | 15 | 14 | 15 | 8-12 |

| Mechanical Finish | Singeing, calendaring, heat-set | Singeing | |||||

| Chemical Finish | membrane | Water and oil repellent | PTFE impregnated peritoneal | ||||

| Warp Of Stretch Strength | 800 | 1000 | 600 | 1400 | 900 | 900 | 900 |

| Welf Of Stretch Strength | 1200 | 1300 | 800 | 1600 | 1200 | 1200 | 1200 |

| Resistance to Acid | Medial | Fair | Excellent | Excellent | Excellen | Excellent | Fair |

| Resistance to Oxidation | Excellent | Good | Excellent | Excellent | Excellent | Poor | Fair |

| Resistance to Alkali | Medial | Poor | Excellent | Excellent | Excellent | Excellent | Good |

| Resistance to Hydrolysis | Medial | Poor | Excellent | Fair | Excellent | Excellent | Fair |

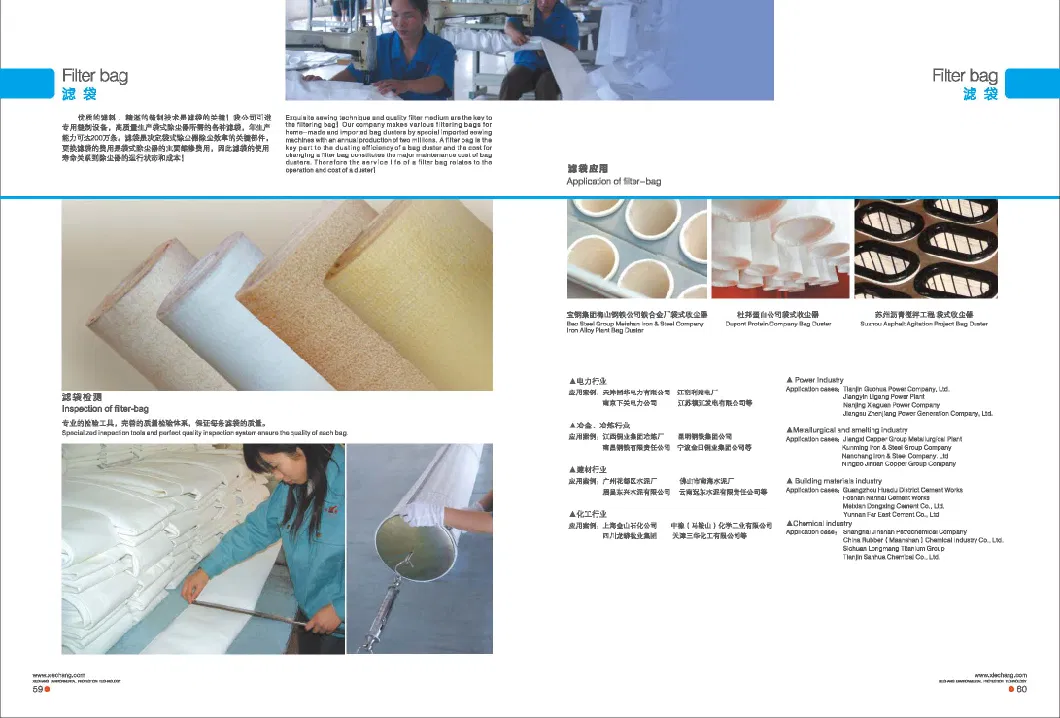

| Application | 1) The fume and smoke treatment and particle removing system in metallurgy plant 2) Smoke filtration in garbage burning, coal-feed boiler,power plant 3) Asphalt concrete mixture, cements, chemical,ceramics, building materials 4) Dust treatment, purification and collection in electronics, mining, flour and timber processing | ||||||

| Size | Φ4'' ; 5'' ; 5.25'' 6'' ; 6.62'' Length: 18'' up to 192'' | ||||||

| Filter Bag Top Construction | 1) Side Load: raw edge top (3" longer than split collar cage length) 2) Top Load: snap band/ring ; double beaded | ||||||

| Bottom Construction | 1) Single-ply felted disc bottom 2) 3" bottom; double-ply wearguard 3) 5" wear cuff with 2" overhang below bag disc bottomBottom Construction | ||||||

1.The material of the polyeser filter bag:

(1) 100% POLYESTER

(2) ANTI-STATIC POLYESTER

(3) 100% POLYPROPYLENE

(4) HOMOPOLYMER ACRYLIC

(5) NOMEX (ARAMID)

(6) RYTON (PPS)

(7) P-84 (POLYIMIDE)

(8) GLASSFIBER

2. The filter cage could be carbon or stainless steel material with veturi tube. It could be also split filter cage in two or three pieces construction for easy installation on the site. Filter cage could be 8, 10, 12, 14, 16, 18, 20, 24 number of 3mm or 4mm veritcal bars.

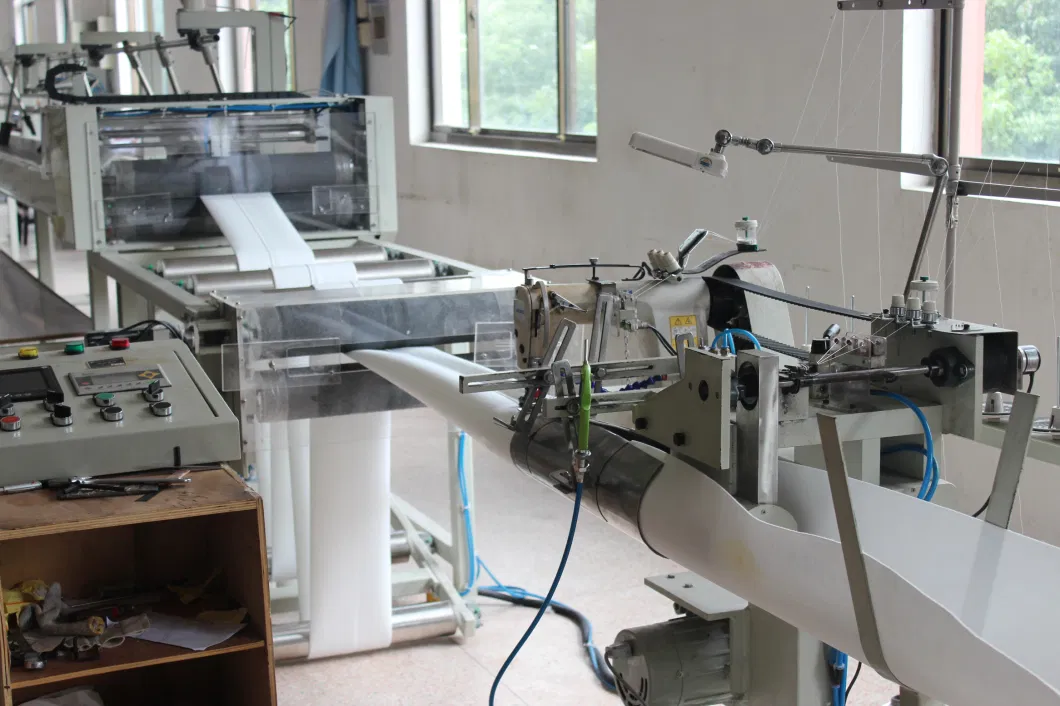

3.Our company imported from Japan the three-needle and six-thread sewing unit that produces duster bags specially and can process bags f different shapes to the users requirement including round, trapezoidal, flat and profiled filter bag.

4.We can provide two different kinds of the filter bags, one is external filter bag, the other one is internal filter bag.

We can meet the different requirment of media and type!