Woven Fiberglass Filter Bags for Cement Plant Dust Filtration 292X10000mm

Basic Info.

| Model NO. | 130*6000 |

| Filtration Grade | Medium Filter |

| Filter Bag Sectional Shape | Round Bag |

| Filter Bag Environment | High-Temperature |

| Cartridge Installation | Vertical Lifting |

| Package | Carton Box |

| Transport Package | Carton Box |

| Specification | 160x6000mm |

| Trademark | OEM |

| Origin | China |

Product Description

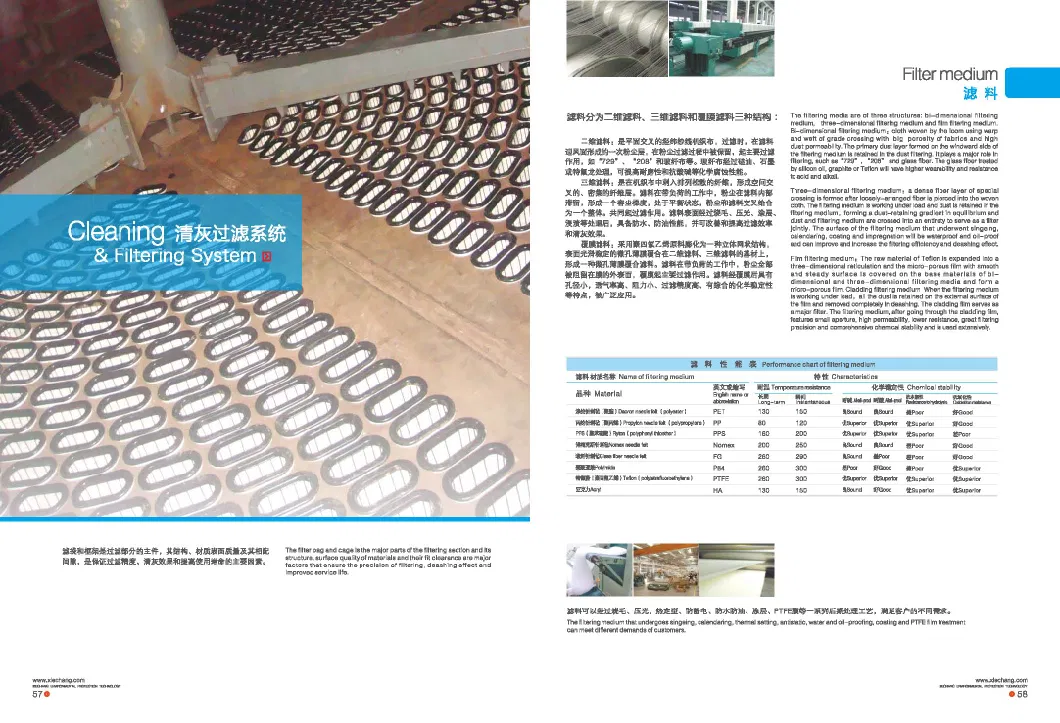

woven Weave Black Fiberglass Cloth filter used for filter bag

This kind of glass fabric is used for making filter bag. It's used in cement, steel plant and so on.

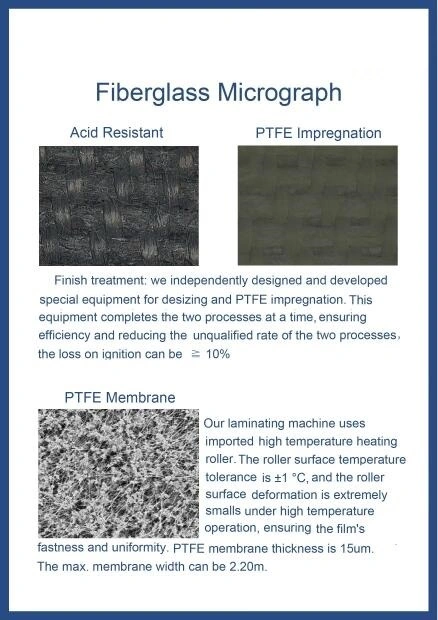

Triple finish: The triple finish was one of the earliest finishes developed for filtration from chemical attack. The triple finish is now used primarily in cement production and metal foundry applications.

PTFE finish: A ten Percent add on of PTFE particles, such as Dupont's PTFE B, encapsulates the glass fibers to prevent abrasion. However, because PTFE don't bond to the glass filaments, acids or alkalis can attack fabric with a PTFE finish chemically. Fabric with PTFE finish is recommended for use with utility base load boilers operation under mild PH conditions.

The technical data of Fiberglass filter fabric

Specification | EWTF340 | EWTF470 | EWTF750 | |

Weave | 1/3 twill | 1/3 twill | Double twill | |

Finish | TRI | TRI | PTFE | |

Loss on ignition | >10 | >10 | >10 | |

Density(pics/cm) | 21×12 | 17×9 | 19×16 | |

Weight(g/m2) | 380±10 | 520±20 | 820±20 | |

Tensile strength(N) | Warp | >1900 | >2300 | >25000 |

Weft | >1550 | >180 | >22000 | |

Air permeability(cm3/cm2/s) | 30-45 | 28-45 | 20-30 | |

Mulen burst(kpa) | 3600 | 4150 | 6200 | |

MIT flex(times) | Warp | 100000 | 150000 | 210000 |

Weft | 75000 | 140000 | 200000 | |

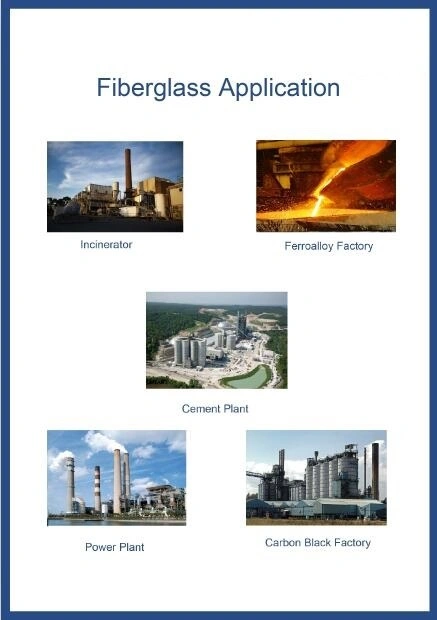

Application: Iron and Steel, smelting, Ferroalloy, Chemical Engineering, cement, calcium Carbide, waste incineration, Electric Power, Asphalt mixing

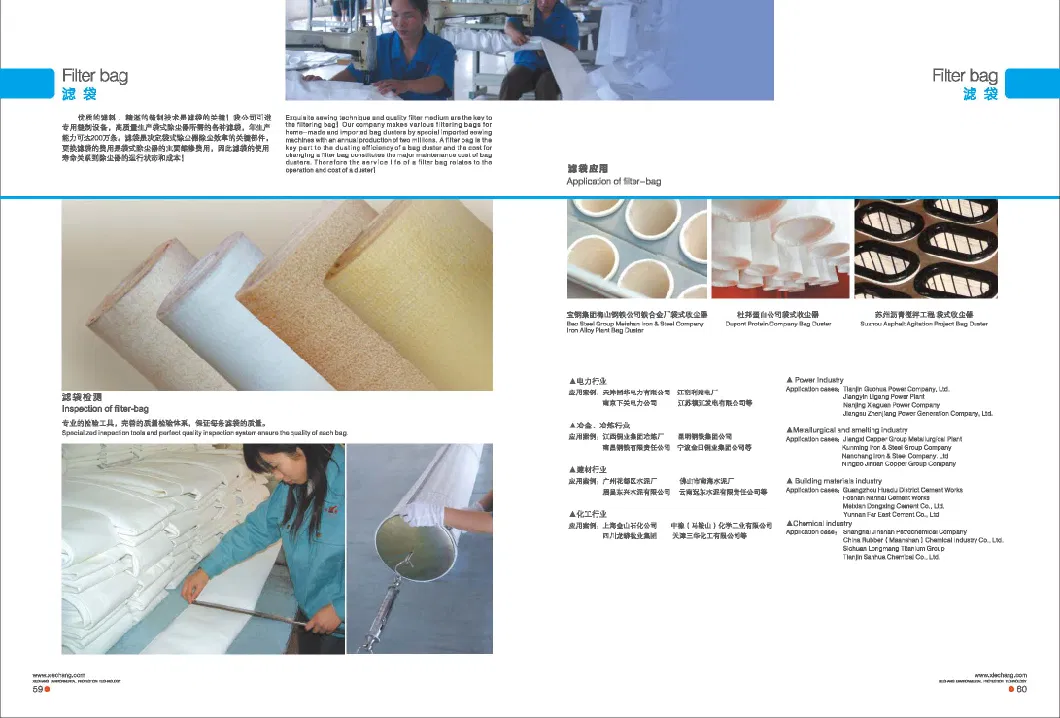

1.The material of the dust collector filter bag:

(1) 100% POLYESTER

(2) ANTI-STATIC POLYESTER

(3) 100% POLYPROPYLENE

(4) HOMOPOLYMER ACRYLIC

(5) NOMEX (ARAMID)

(6) RYTON (PPS)

(7) P-84 (POLYIMIDE)

(8) GLASSFIBER

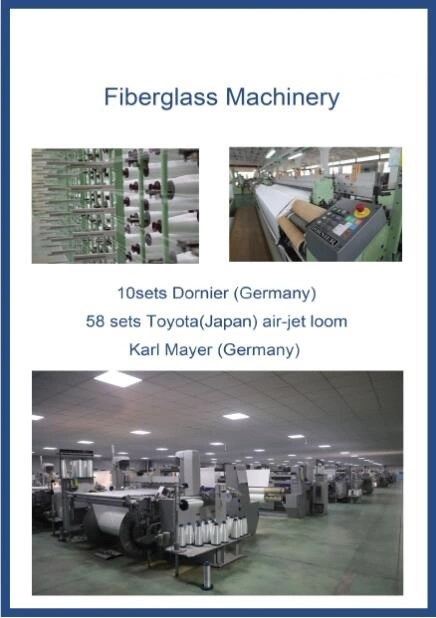

2.Our company imported from Japan the three-needle and six-thread sewing unit that produces duster bags specially and can process bags f different shapes to the users requirement including round, trapezoidal, flat and profiled filter bag.

3.We can provide two different kinds of the filter bags, one is external filter bag, the other one is internal filter bag.

We can meet the different requirment of media and type!